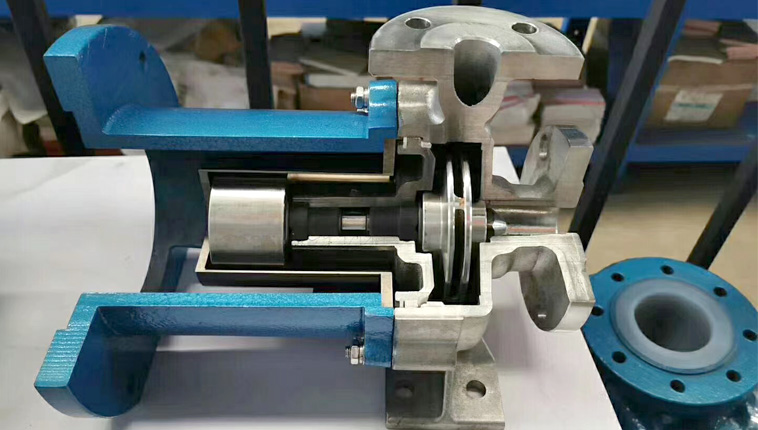

1, the magnetic pump can not be idling, because the magnetic pump of the magnetic cylinder is composed of cooling medium, if the air will cause the magnetic cylinder lock.

2, magnetic pump rotor bearings are mostly made of cemented carbide, lubricated by the medium, the pump can not be lubricated.

4. The core components of the magnetic pump are external magnetic components and internal magnetic components. If idling, the core components will be degaussed at high temperatures and the performance of the magnetic pump will greatly reduce post-demagnetization.

+86 18130251359

+86 18130251359 teflowpumps@tlpumps.com

teflowpumps@tlpumps.com

+86+0563-5093318

+86+0563-5093318